From basic tools, residents in Thong Nhat Commune (Thuong Tin, Hanoi) could produce simple and useful glassware like light bulbs, bottles, vases, vacuum flask stoppers or any other delicate products according to customers’ demands.

Since the 1960s, glass blowing has been the main source of income for most of the local people in Thong Nhat Commune. Among villages in the commune, Giap Long Village is the most developed area with a large number of skilled workers who can produce complicated and delicate glassware.

According to Le Xuan Tien, who has more than 20 years experience in glassware making in Thong Nhat Commune, ten years ago almost all villagers did this job. They could make any household product like bottles, vases or vacuum flask stoppers.

Glassware production is a traditional craft in Thong Nhat Commune (Thương Tin District, Hanoi).

Glass blowing has existed in Thong Nhat Commune over the years.

After being heated, molten glass is blown and pressed to form desired shapes.

The work requires intense concentration.

Decorating products.

Completed products are buried in chaff to maintain their fastness.

Each day, hundreds of glass products are produced in Thong Nhat Commune

Oil lamp’s bulbs are a main product of the village.

Completed bird food containers. |

In order to make good products, the glassblowers should know glass very well. When glass is put into fire, it is green; when molten glass turns transparent, it is ready to be blown. Then, glassblowers just need to slightly blow to introduce air to the molten blob of glass to make it expand into desired shapes.

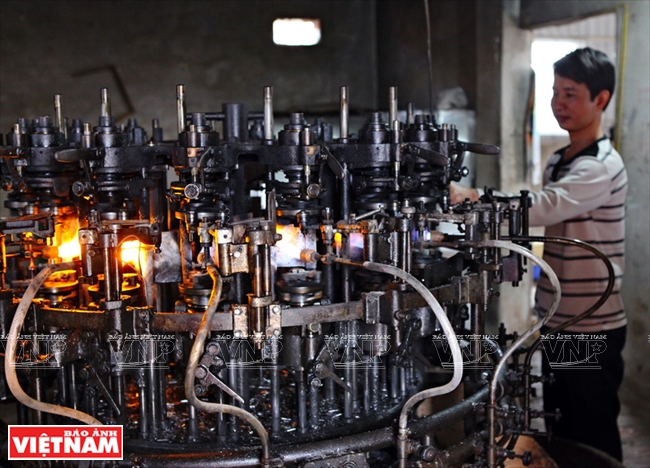

With an ever increasing demand from customers, many households in Thong Nhat Commune have invested in modern machines to mass produce medical instruments such as glass ampoules.

Nguyen Van Hue, owner of an ampoule producing workshop in Giap Long Village, acknowledged that in 2010 he invested in a machine with a capacity of around 100kg of glass products (approximately 10,000 ampoules) a day.

Many households in the village have invested in modern machines

to produce glassware in a large number.

Material glass tubes are made manually before being put in machines.

Glass tubes are heated and shaped automatically.

A workshop owner in Thong Nhat Commune acknowledges that

a glassblowing machine can replace 20 to 30 glassblowers. |

With mounting orders, in early 2014, he bought another new machine with the double capacity to timely produce a huge volume of products ordered by domestic and foreign pharmaceutical firms. So far, three out of five villages of Thong Nhat Commune, namely Hoang Xa, Thuong Giap and Giap Long communes, have workshops with modern machines to produce medical instruments, he said.

As strenuous and low-paying as it is, glassblowing still develop in Thong Nhat Commune with residents who keep firing the blazing furnaces in preservation of their traditional craft.

Story: Quynh Anh – Photos: Cong Dat